Pneumatic punch helps hardware realize efficient production transformation

In the highly competitive hardware processing industry, XX hardware once fell into the development bottleneck because of the low efficiency and high energy consumption of traditional punch equipment. The average daily output of the enterprise is less than 5000 pieces, and the defective rate of products is as high as 8% due to the poor stability of equipment. Frequent equipment failures have led to many delays in delivery and constant customer complaints.

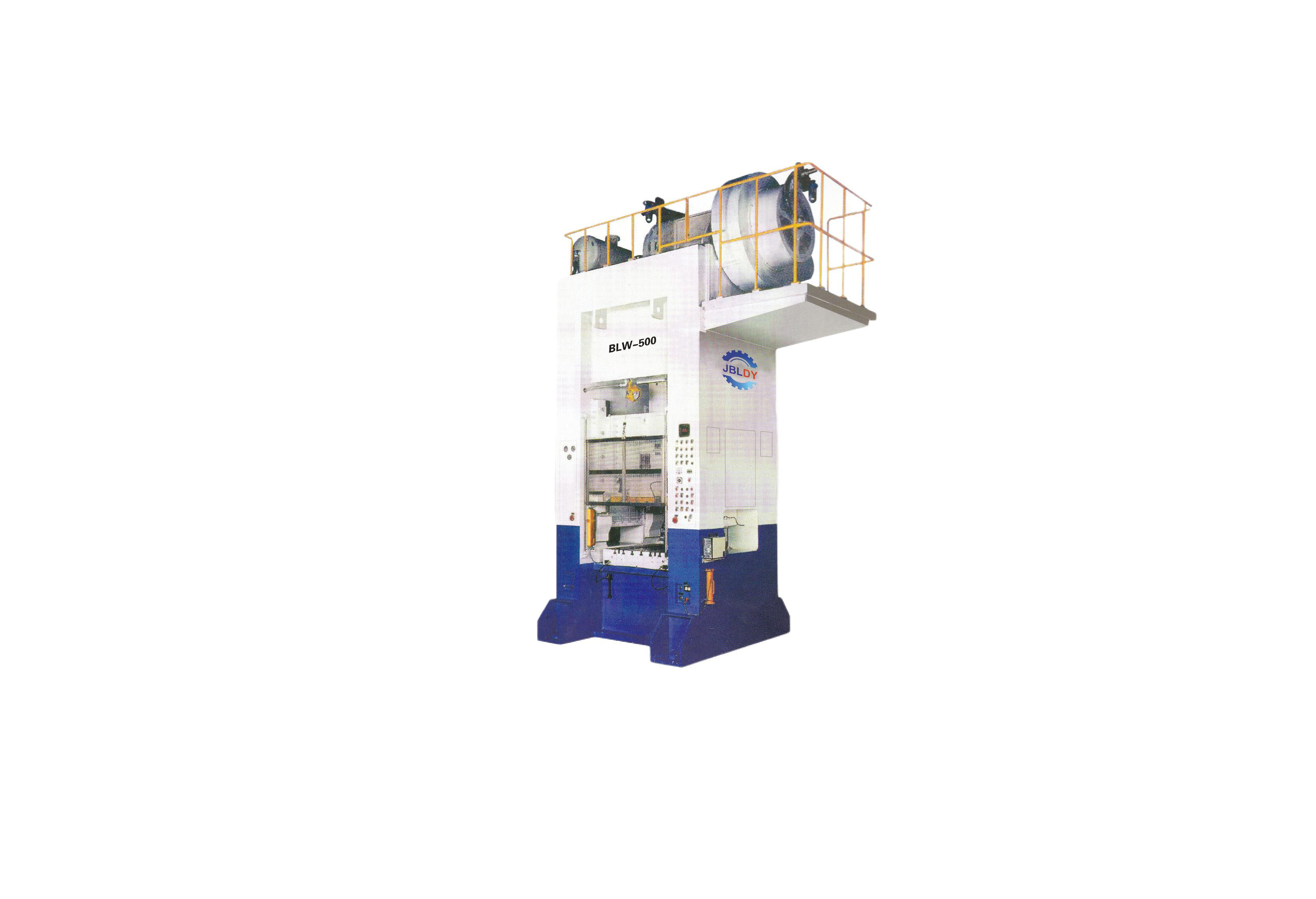

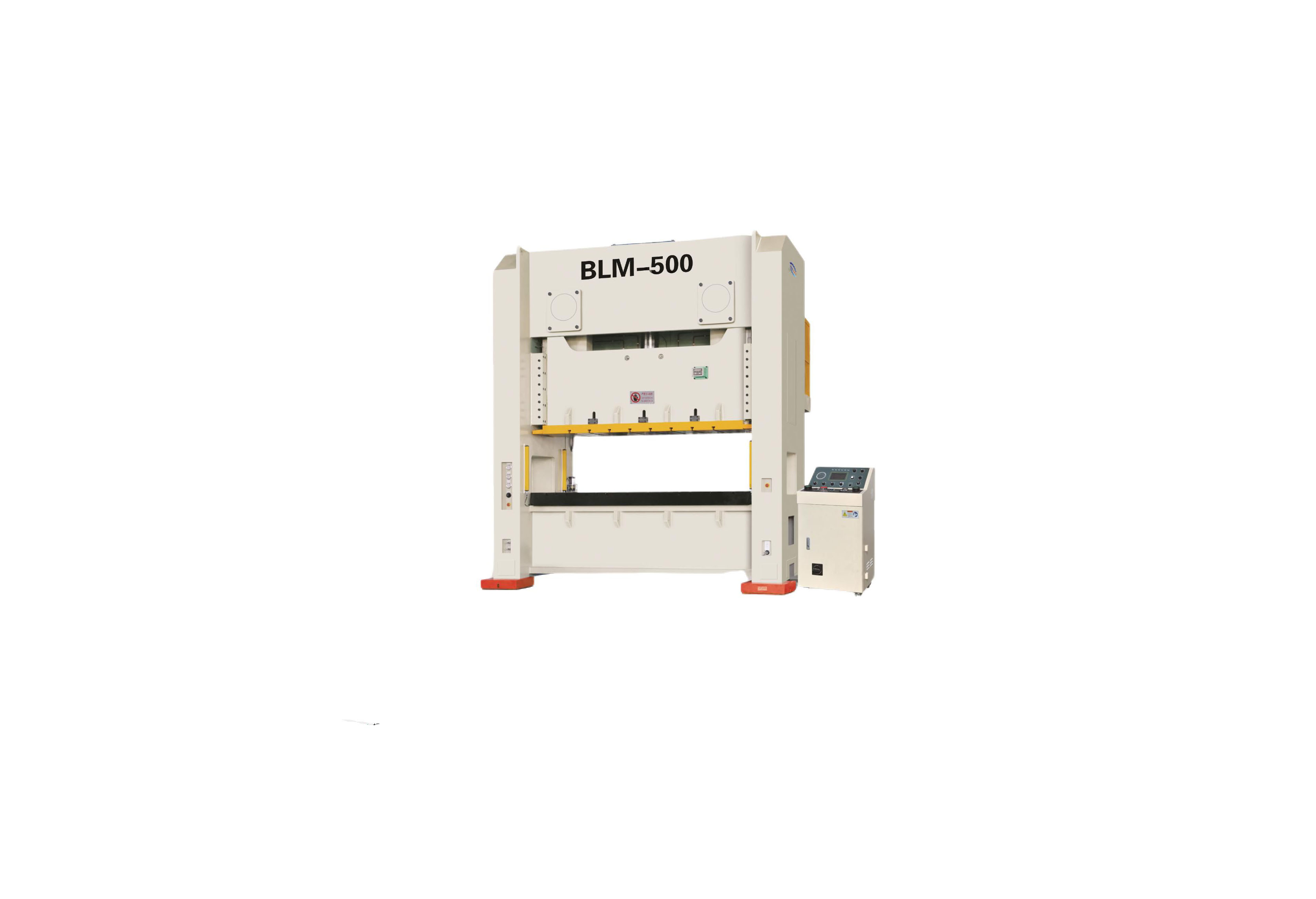

In order to break through the predicament, XX Hardware introduced a new pneumatic punch. The equipment is powered by compressed air, and its response speed is extremely fast. The punching times per minute can reach 200 times, which is three times higher than that of traditional equipment, and the average daily output has jumped to 15,000 pieces. At the same time, the pressure output of pneumatic punch is accurate and adjustable, and with intelligent control system, the defective rate of products drops to 1.5%. In addition, its energy consumption is only 60% of that of the traditional punching machine, and the annual electricity saving exceeds 120,000 yuan. With stable and efficient production performance, XX Hardware has successfully won orders from many well-known enterprises, with an annual output growth of over 40%, achieving a gorgeous turn from the edge of the industry to a regional leader.