Pneumatic punch helps hardware realize efficient production transformation and market breakthrough

With the fierce competition in the hardware manufacturing industry, equipment performance and production efficiency have become the key for enterprises to win. XX Hardware, a medium-sized manufacturing enterprise that struggled in the traditional production mode, achieved the counterattack from being on the verge of elimination to the industry benchmark by introducing pneumatic punch, and its transformation process can be called an industry model.

Difficulties: traditional equipment hinders the development of enterprises

XX Hardware was established in 2010, mainly engaged in stamping metal parts, serving the fields of home appliances and auto parts. In the early days, it relied on traditional mechanical punch to maintain production, but with the increase of order volume and the improvement of customer requirements, the shortcomings of equipment became increasingly prominent. The mechanical punching machine can only complete 60 punches per minute, with an average daily production capacity of only 5,000 pieces. When facing orders in peak season, the production line often needs 24 hours of continuous rotation, which is still difficult to meet the delivery demand. Not only that, the pressure control of equipment is rough, and the deviation of stamping accuracy is large, which leads to the long-term poor product rate of around 8%, and the direct loss caused by waste products is as high as 50 thousand yuan per month.

Frequent equipment failures are even worse. Due to the complex mechanical structure and serious wear of key components, the monthly equipment downtime is as long as 40 hours, which directly affects the delivery cycle. In 2020, due to the delay in delivery, XX Hardware lost three important customer orders one after another, and its corporate reputation was damaged. Its revenue decreased by 15% year-on-year, and it fell into a development dilemma.

The choice of breaking the game: pneumatic punch opens the road to transformation

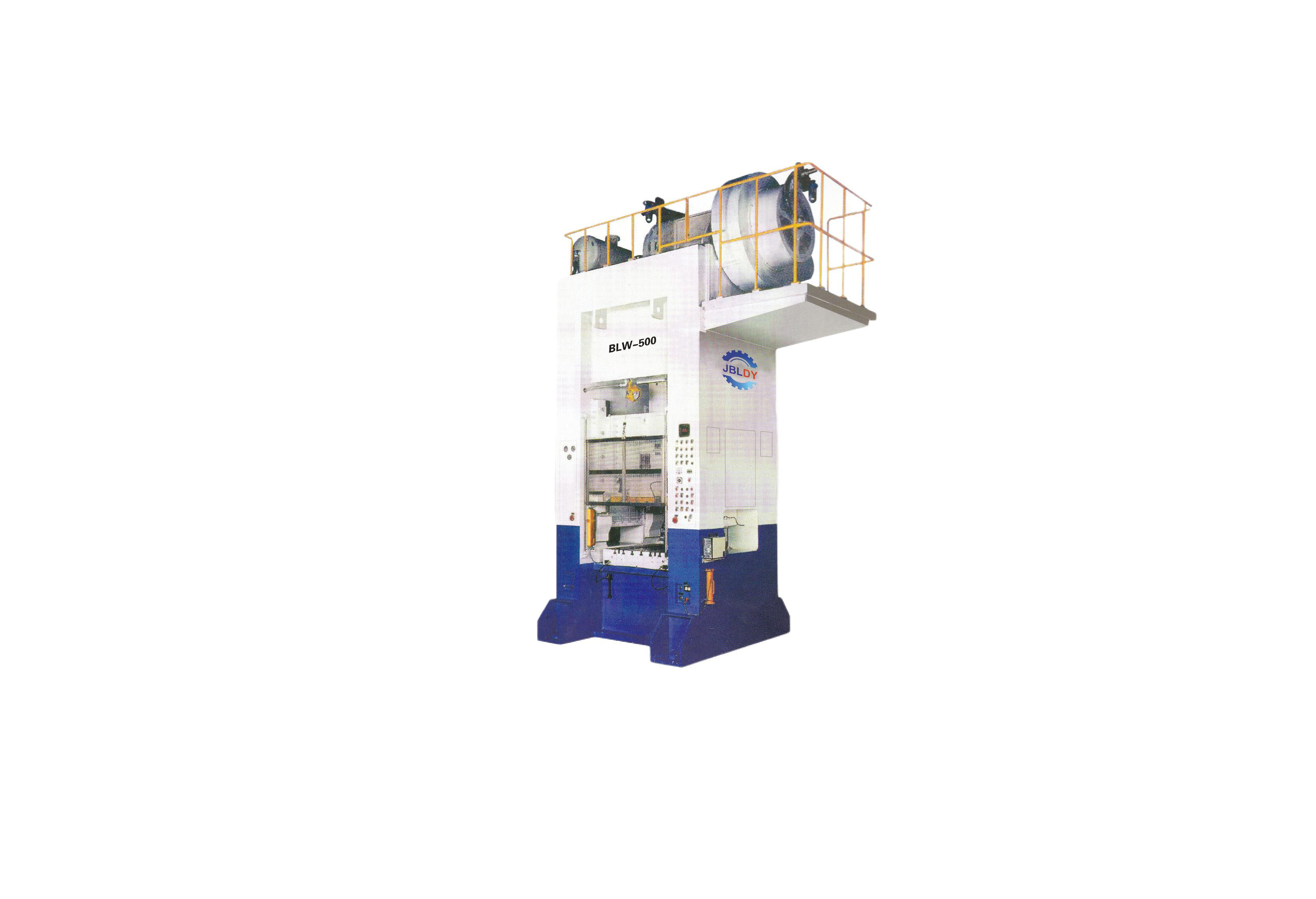

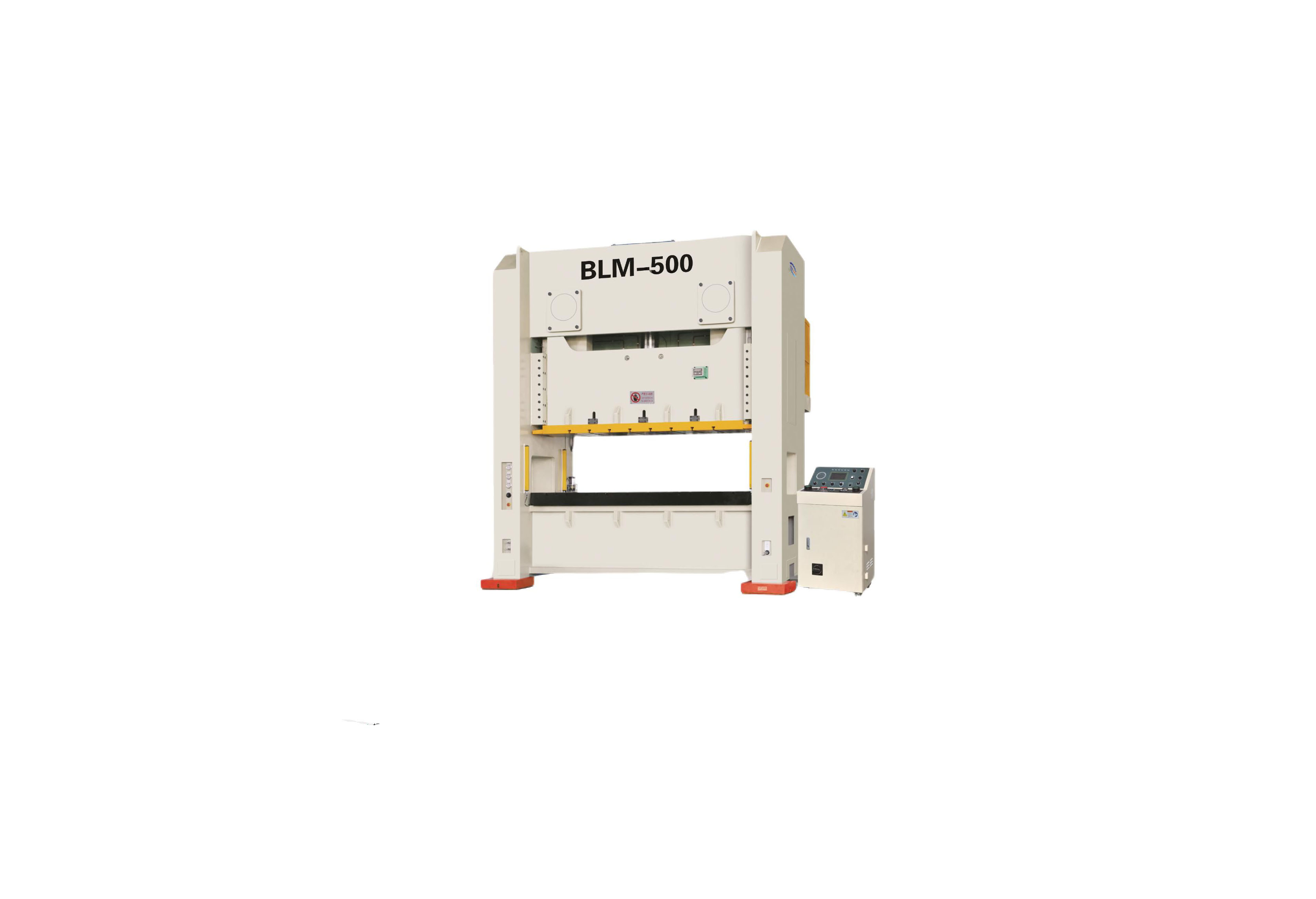

In order to reverse the decline, XX Hardware Management organized technical teams to inspect the cutting-edge equipment in the market for many times, and finally set their eyes on pneumatic punching machines. Compared with traditional mechanical punch, pneumatic punch takes compressed air as power source, which has obvious advantages such as fast response speed, accurate pressure output, energy saving and environmental protection. After many comparisons and technical demonstrations, XX Hardware invested 2 million yuan to introduce five high-performance pneumatic punching machines, and simultaneously intelligently transformed the workshop layout.

In the stage of equipment installation and debugging, the enterprise invites technical experts from equipment manufacturers to give on-site guidance, and organizes internal employees to carry out special training for two weeks, covering equipment operation, basic maintenance and troubleshooting. At the same time, a new equipment operation monitoring system is established to collect data such as stamping times, pressure value and energy consumption in real time, which provides a basis for subsequent optimization of production processes.

Remarkable results have been achieved: both production and efficiency have been improved.

After the new pneumatic punch was put into use, the production efficiency increased by leaps and bounds. Its maximum punching frequency is 200 times per minute, which increases the daily average production capacity of a single production line to 15,000 pieces, which is three times higher than that before the transformation, and the bottleneck of enterprise production capacity is completely broken. In terms of pressure control, the pneumatic punch is equipped with intelligent control system, and the pressure accuracy can reach 0.5%. With high-precision molds, the defective rate of products drops to 1.5%, and the loss of waste products is reduced by over 600,000 yuan every year.

Energy consumption performance is equally bright. The energy consumption of pneumatic punching machine is only 60% of that of traditional mechanical punching machine, and the monthly electricity expenditure of enterprises is reduced from 100,000 yuan to 60,000 yuan, saving 480,000 yuan annually. In addition, the equipment has simple structure and convenient maintenance, the maintenance period is extended from once a month to once a quarter, and the single maintenance time is shortened from 8 hours to 2 hours, which greatly reduces the equipment maintenance cost and downtime loss.

Market Breakthrough: Winning the Right to Speak in Industry with Strength

The double promotion of production efficiency and product quality makes XX hardware stand out in the market competition. With stable and efficient delivery capacity, the company has successfully established long-term cooperative relations with many well-known home appliance brands and auto parts suppliers. In 2022, the amount of new contracts signed by enterprises exceeded 80 million yuan, and the annual output value increased by 40% year-on-year, which doubled before the transformation.

Today, XX Hardware has become a benchmark enterprise in hardware manufacturing in the region, attracting many peers to visit and study. The enterprise plans to continue to expand the application scale of pneumatic punching machine, introduce automatic production line and digital management system, and move towards intelligent and high-end manufacturing, providing a model for industry transformation and upgrading.