Pneumatic punch helps jewelry enterprises to achieve a new leap in exquisite production

In the field of jewelry manufacturing, which pursues the ultimate craftsmanship and details, every product is the crystallization of ingenuity and art, and the fineness and flexibility of production equipment have become the key for enterprises to build high-end quality. XX Jewelry Co., Ltd. once fell into a bottleneck in product quality, production efficiency and customized service due to the limitations of traditional stamping equipment, and our pneumatic punching machine brought it a brand-new development opportunity and opened a new chapter in exquisite production.

XX Jewelry Co., Ltd. focuses on the production of precious metal jewelry such as gold and platinum and inlaid jewelry. Traditional stamping equipment is cumbersome and inefficient in the face of complicated and diverse modeling design of jewelry, and can only complete 12 stamping operations per minute. In case of peak orders such as holiday promotion, delivery is often delayed due to insufficient production capacity, and the customer complaint rate is as high as 35%. What is even more difficult is that the stamping accuracy of traditional equipment is only 0.1 mm. For jewelry inlaid products, this error can easily lead to problems such as unstable gemstone inlay and uneven surface of jewelry, and the defective rate of products is as high as 22%, which not only wastes expensive precious metals and gemstone raw materials, but also seriously affects the brand reputation. In addition, the maintenance of traditional equipment is complicated, and it costs 60,000 yuan per month for equipment maintenance and parts replacement, which further reduces the profit margin of enterprises.

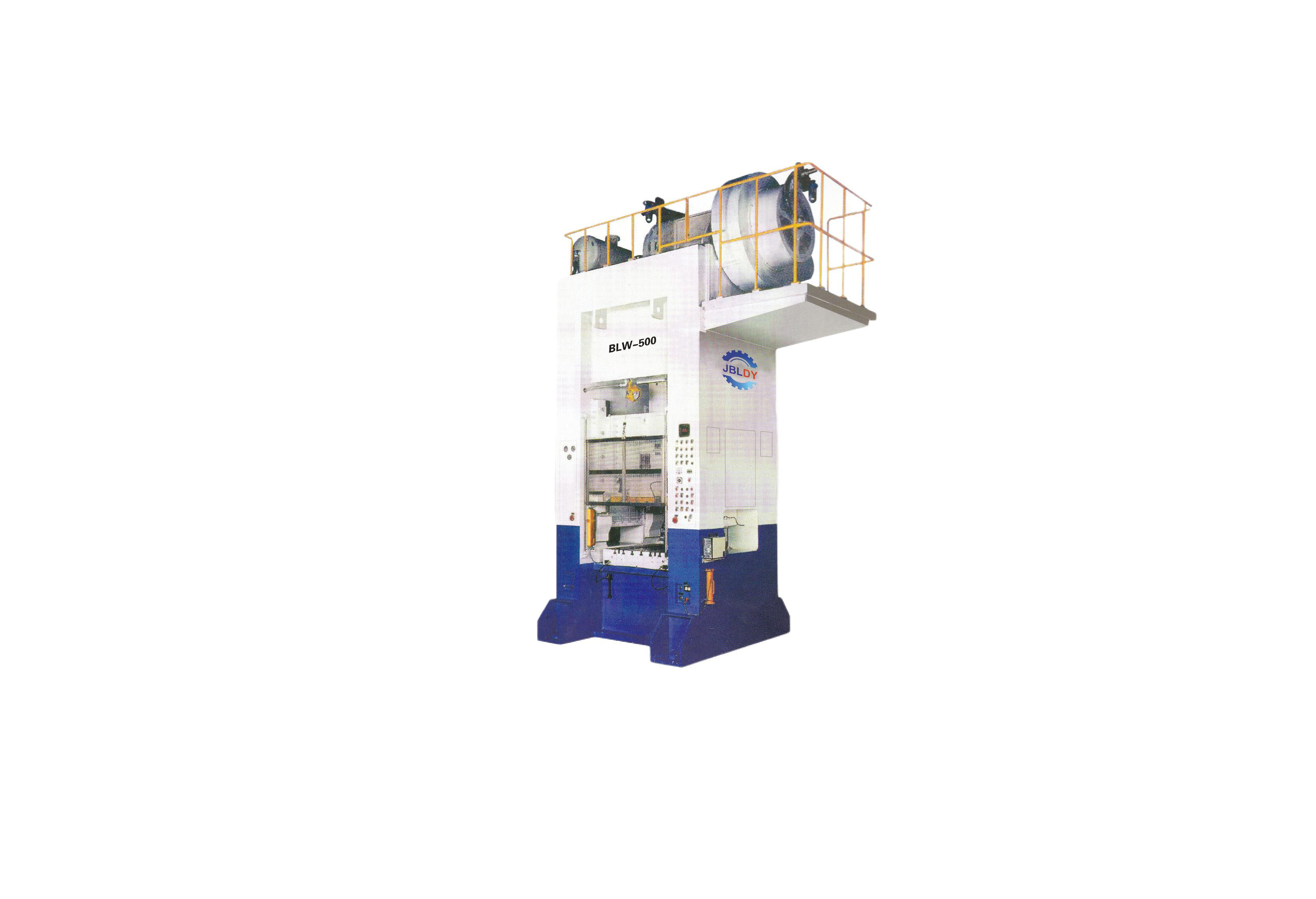

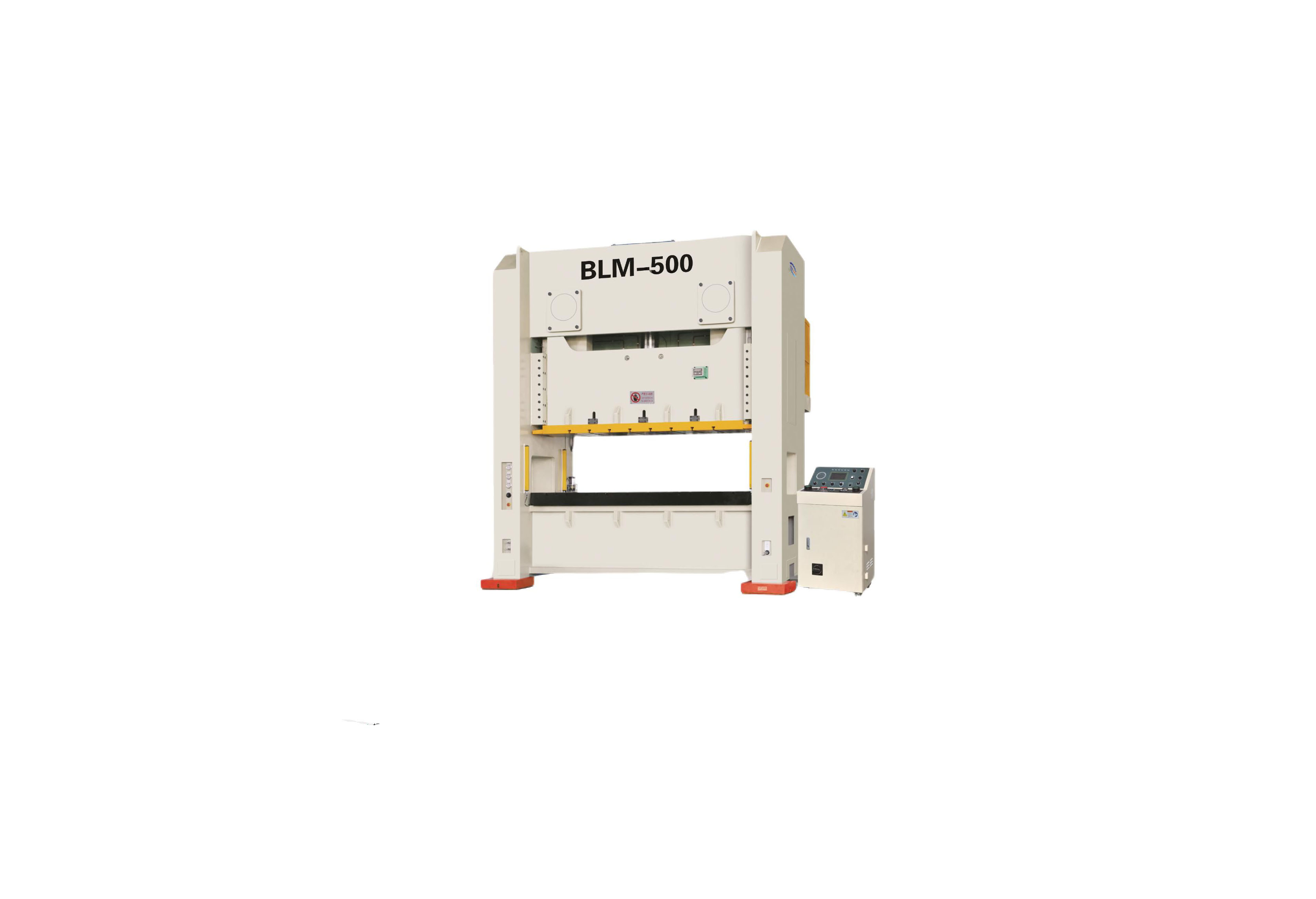

In order to break through the development dilemma, XX Jewelry Co., Ltd. decided to introduce our [customized model] pneumatic punch. With the advanced pneumatic servo drive technology, this equipment has increased the stamping speed to 45 times per minute, and the production capacity has increased by nearly three times. Even in the outbreak of orders, it can be delivered on time, and the customer complaint rate has dropped significantly to 8%. In terms of accuracy, its micron-scale precision control system enables the stamping accuracy to reach ±0.01mm, which perfectly meets the ultimate pursuit of details in jewelry. The gem setting firmness of inlaid products is significantly improved, the surface of jewelry is as smooth as a mirror, and the defective rate of products drops to 5%. It has successfully created a series of high-end products and won high recognition from consumers.

It is worth mentioning that our pneumatic punching machine has strong flexible production capacity. By changing different molds and adjusting parameters, we can quickly realize the production switching of diversified products and meet the personalized customization needs of customers. The equipment also adopts humanized operation interface, and combined with 3D simulation stamping function, the operator can visually preview the stamping effect, greatly reducing the operation difficulty and error rate; At the same time, it is equipped with intelligent safety protection curtain and pressure overload protection device to ensure the safety of operators in all directions. In addition, the modular design makes equipment maintenance easy and convenient, and the maintenance cost is reduced by 70%.

Since the use of our pneumatic punching machine, XX Jewelry Co., Ltd. has achieved an annual output increase of 150% within one year, successfully launched a number of explosive products, and its brand awareness and market share have been rising, and it has also reached cooperation with many international high-end jewelry brands. Today, the company has become a model of exquisite production in the jewelry manufacturing industry.

Whether it is jewelry manufacturing that pursues exquisite craftsmanship or other industries that require high accuracy and flexibility, our pneumatic punching machines can provide suitable solutions. Choosing us means choosing excellent quality and efficient production. We look forward to working with you to carve a bright future for the industry!