Pneumatic punch helps toy enterprises to realize efficient and safe production.

In the toy manufacturing industry, the production efficiency, quality safety and cost control of products are directly related to the market competitiveness and brand image of enterprises. XX Toy Manufacturing Co., Ltd. once encountered many problems in the production process because of the backwardness of traditional stamping equipment, and our pneumatic punching machine has brought it a new experience of efficient, safe and stable production, helping enterprises to stand out in the fierce market competition.

XX Toy Manufacturing Co., Ltd. mainly produces plastic toys, educational toys and other products. The traditional stamping equipment used in the past has extremely low production efficiency, and can only complete 15 stamping operations per minute. In the peak season of sales such as Children's Day and Christmas, the production line is often overloaded, and the delivery delay becomes the norm, resulting in serious customer loss, and the order loss rate is as high as 30%. In terms of product quality, the stamping accuracy of traditional equipment is limited, and the error reaches ±0.3mm, which leads to inaccurate dimensions of toy parts, easy loosening and excessive gaps after assembly. The defective rate of products is as high as 25%, which not only wastes a lot of plastic raw materials, but also causes many customer complaints due to potential safety hazards. In addition, traditional equipment is noisy, energy-consuming, and difficult to maintain. The monthly equipment maintenance cost is as high as 45,000 yuan, which seriously affects the profit margin of enterprises.

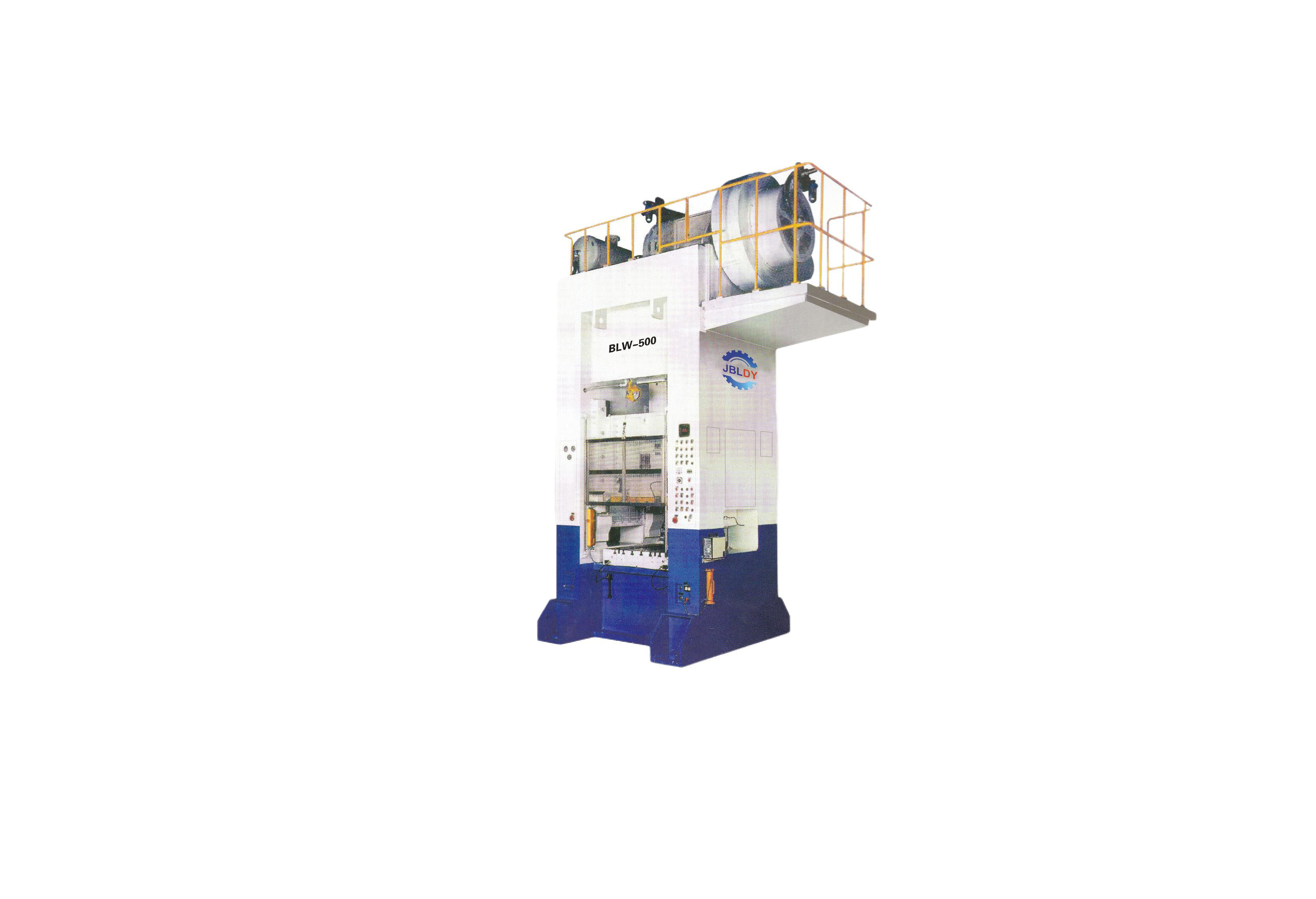

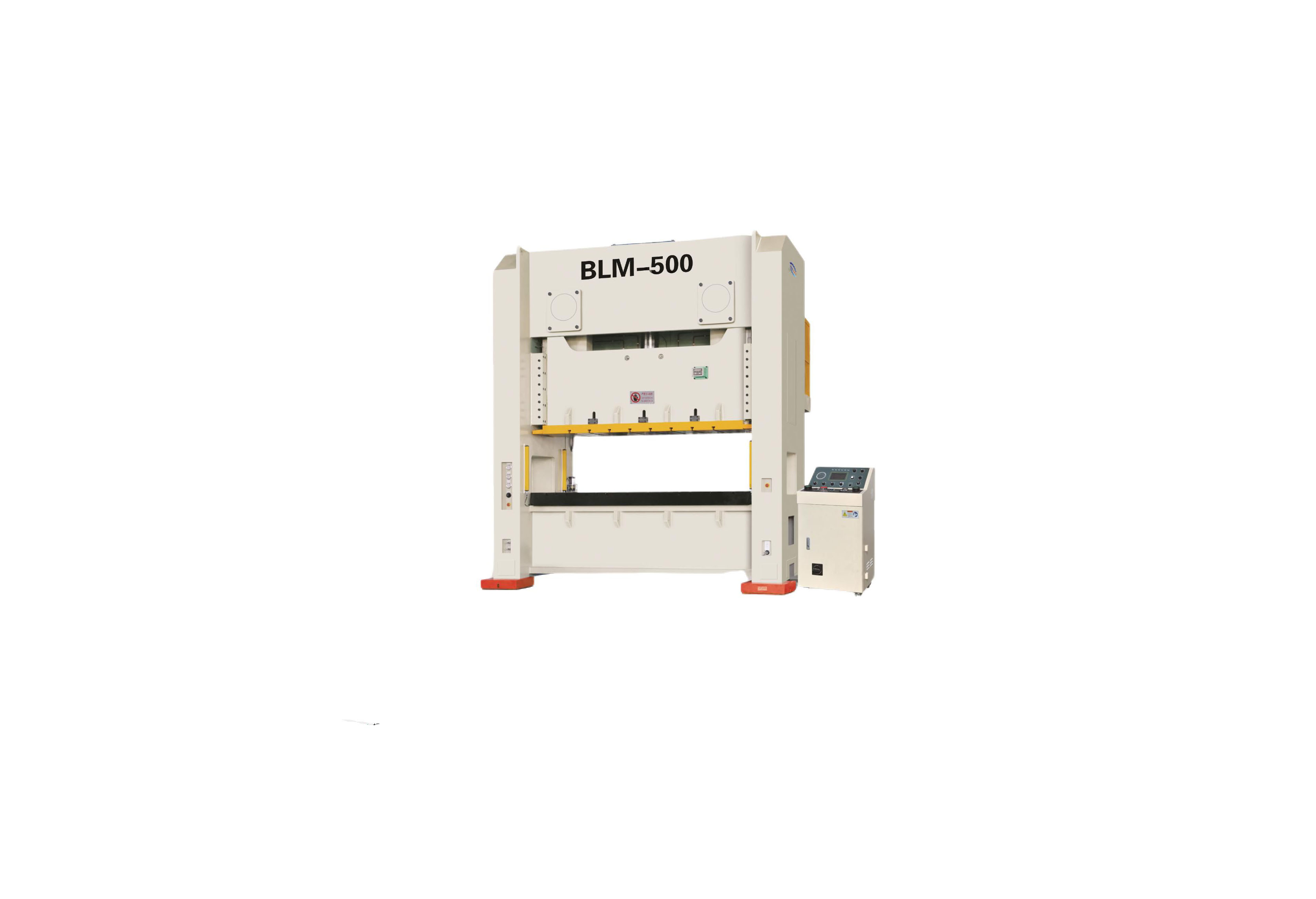

In order to improve the present situation, XX Toy Manufacturing Co., Ltd. finally chose to introduce our [high-efficiency model] pneumatic punch after in-depth investigation and comparison. This pneumatic punching machine adopts innovative pneumatic driving technology, the punching speed is greatly increased to 50 times per minute, and the production capacity is increased by 233%. Even in the peak sales season, it can easily cope with the order peak, and the delivery punctuality rate is increased to 98%, which successfully saves a large number of customers and the order volume is significantly increased. In terms of precision control, its high-precision positioning system improves the stamping precision to ±0.05mm, and the size of the toy parts produced is accurate. After assembly, the product quality is stable, and the defective rate of products drops to 5%, which effectively guarantees the safety and reliability of products and has been widely recognized by the market.

At the same time, our pneumatic punching machine has excellent environmental protection and energy-saving characteristics. Compared with traditional equipment, the noise is reduced by 40% and the energy consumption is reduced by 30%, which is in line with the concept of green production. The equipment also adopts intelligent operation interface and convenient modular design, so that operators can get started quickly, and the equipment maintenance becomes simple and efficient, and the maintenance cost is reduced by 60%. In addition, the pneumatic punching machine is equipped with all-round safety protection devices, such as two-hand start button, emergency braking system and safety fence, which can effectively avoid accidents of operators in the production process and escort the safe production of enterprises.

Since the use of our pneumatic punch, XX Toy Manufacturing Co., Ltd. has reduced the production cost by 20% and increased the annual output value by 80% in just half a year, successfully launched a number of best-selling toy products, and greatly improved its brand awareness and market share. Today, the company has become a benchmark enterprise for efficient production and quality assurance in the toy manufacturing industry.

With the rapid development of toy manufacturing industry, our pneumatic punching machine provides professional production solutions for enterprises with the advantages of high efficiency, accuracy, safety and energy saving. Whether you need to increase production capacity, ensure product quality or reduce production costs, we can customize the exclusive production plan according to your actual needs. Choosing our pneumatic punch is to choose a more efficient, safer and more competitive future. We look forward to working with you to create the brilliance of toy manufacturing industry together!